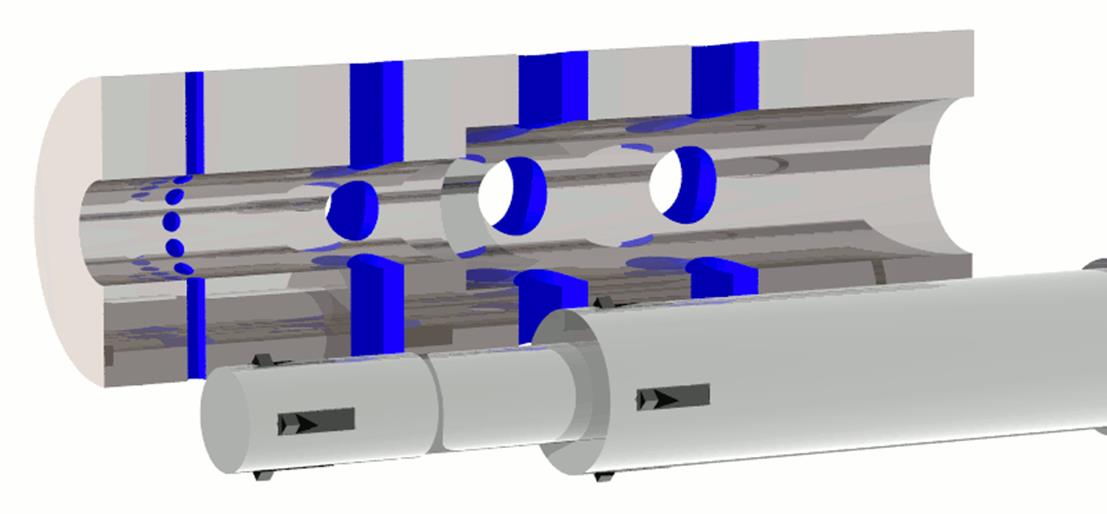

HSD high speed deburring tool - function introduction (suitable for deburring all kinds of heterosexual cross holes)

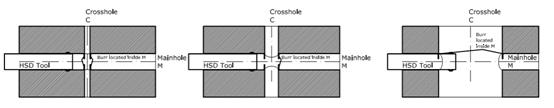

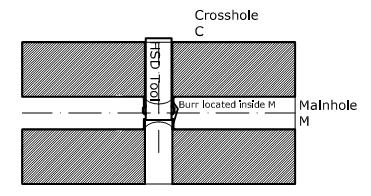

1. Internal action: the tool rotates clockwise into the main hole.

| |

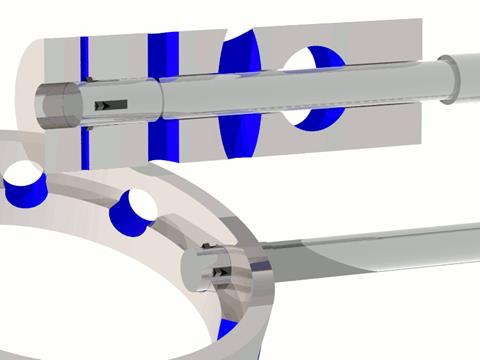

2. Through the main hole: the tool is processed with working feed until the root of the main hole. In this process, the burrs of all through holes as shown in the figure can be removed.

| |

2.a) The blade is hidden in the cutter arbor and is in a retracted state

|

|

2.b) Blade in process: the blade opens in the through hole

|

|

3.Tool retraction: after the tool is processed to the bottom of the workpiece, stop feeding, the spindle reverses and retracts, and exits at the same processing feed speed. Complete chamfering is completed.

| |

HSD technical features

·Floating blade rotary deburring tool

·The blade floats in the arbor by pressure

·The cutting force of the blade can be adjusted by using cooling oil, coolant or compressed air

·The deburring effect will be affected by the following factors: the pressure of cooling oil, compressed air or coolant; Feed rate; Spindle speed.

·High speed and high feed can be used

Advantages of HSD tools (differences in working methods)

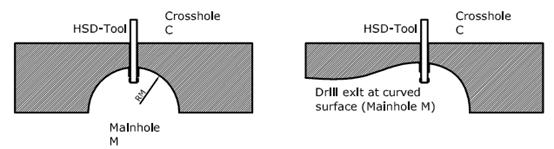

·HSD tool belongs to pressure control tool, which can process complex inclined through holes (except 1:1 axial and transverse holes and elliptical holes), as well as longitudinal grooves and steps.

·HSD deburring tool can process all transverse holes penetrating through main hole through one axial machining of the main hole. Different from other traditional tools, HSD deburring tool does not need to process each transverse hole separately. Save a lot of time and rhythm!

·Through the forward and backward feed processing program and left and right rotation processing, the generation of secondary burr is prevented.

·Through the control of compressed air or coolant, the machining speed of the tool can be very high.

·The blade of HSD tool is flexible and controllable. In this way, the blade can accurately and flexibly remove burrs in the through hole. The cutting force can be adjusted by program.

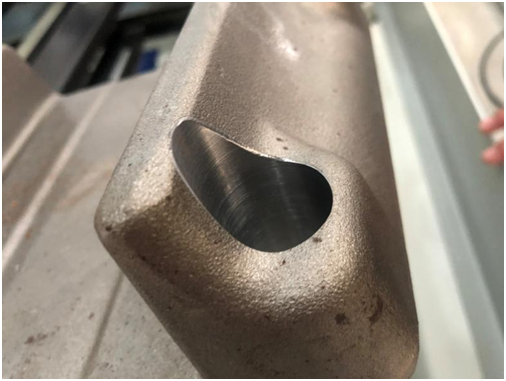

·The tool has no damage to the side wall of the workpiece( However, there will be slight extrusion on the processing part, resulting in certain extrusion marks)

The cutting edge of HSD deburring tool is free without the action of coolant or pressure. It can be processed either through the main hole of the through hole or through the transverse hole of the through hole.

Typical application quick guide Firstly, it is clear what is the main hole and what is the through hole. The diameters of the main hole and the through hole can be different. The main hole is the first drilled hole, the through hole is the later drilled hole, and the burr will be on one side of the main hole. Rule: use HSD deburring tool, preferably in the main hole. |

Case A: first drill the main hole, then drill through the hole, and the burr is on one side of the main hole. HSD deburring tool cuts in the main hole, which is the correct choice of HSD tool. Ignore the diameter ratio of the main hole to the through hole |

Case B1: drill the main hole first, and then drill the through hole. The burr is on one side of the main hole, and the HSD deburring tool cuts from the through hole. Usually, it is impossible to completely remove the burr。

|

Case B2: first drill the main hole, then drill the through hole, the burr is on one side of the main hole, and the HSD deburring tool cuts from the through hole. It is feasible in two cases: 1. For brittle materials (such as cast iron);

|

Click download to view PDF:

HSD cross hole deburring chamfering cutter instruction (programming instruction)

Some customer processing cases:

We will show you the details of deburring tools, floating reamer shanks, rolling heads and diamond rolling cutters provided by our company, as well as the products represented by our company: TOOLFLO, EMUGE, HEULE and other brands

Deburring tools include: integral deburring chamfering cutter, disposable deburring chamfering cutter, HEULE deburring chamfering cutter, HSD deburring chamfering cutter and AKS deburring chamfering cutter handle. Through the above tools, we can provide customers with perfect machining deburring solutions.

Floating reamer handle: we usually call it floating reamer handle or reamer floating reamer handle, which is used to make up for the repositioning error of the machine tool, improve the reamer processing effect and increase the service life of the reamer.

Rolling cutter: also known as rolling head, it has inner hole rolling head, outer circle rolling head, end surface rolling head and other non-standard rolling heads.

Diamond rolling cutter: it is an independent one separated from the rolling head system. There are diamond rolling cutters that can be used to process outer circles and inner holes. At the same time, diamond rolling cutters can also be used for end surface. Through the program control of machine tools, rolling of various shapes can be realized like turning tools. A diamond rolling cutter can cover most of the processing surfaces. Low comprehensive use cost.

简体中文

简体中文

HSD cross hole (through hole) deburring chamfering cutter

HSD cross hole (through hole) deburring chamfering cutter