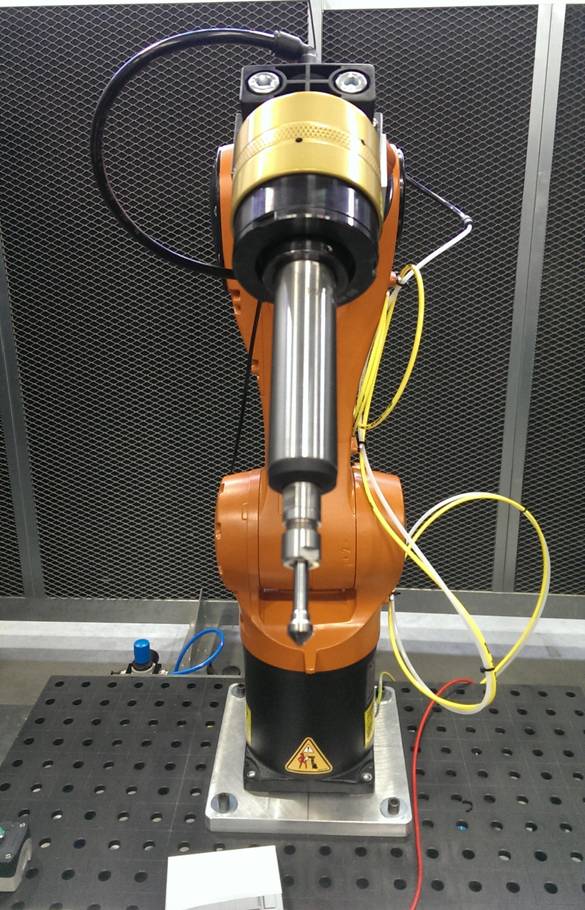

Pneumatic floating deburring chamfering tool handle for FDT PNE X36 robot

To facilitate your simulation, you can click download the 3D图

l FDT PNE X36 robot floating deburring chamfering tool handle

Driven by oil-bearing compressed gas, the tool is designed to remove irregular contour burrs. The lateral pressure of the tool can be adjusted by adjusting the sleeve. The adjustment is mechanical, and the lateral pressing force is adjusted by changing the pressure of the spring. And this pressing force does not change with the change of air pressure.

l Compressed air parameters:

N in order to make the floating deburring handle of the robot operate stably, the compressed air used must be in strict accordance with DNI ISO 8573-1 standard and the quality grade is grade 4. We need a service device as close to the handle as possible. The settings are as follows:

N air pressure: 5-6.3bar (max. 6.3bar),

N inner diameter of gas pipe: 0-6mm (length of gas pipe is less than 2m)

0-10mm (the length of gas pipe is more than 2m)

N usage of pneumatic oil: 2-3 drops / min (1 drop is about 15 cubic mm)

N quality requirements for pneumatic oil: viscosity grade of acid free resin oil = HL32; If the length of the air pipe between the oil filling device and the main shaft exceeds 1m, the use of pneumatic oil needs to be increased to 5-6 drops / min

N the air consumption of the pneumatic spindle is greater than 8.3 L / S (6 bar operating pressure). In order to make the tool handle operate stably and continuously for a long time, try to provide the above-mentioned high-quality compressed air and a minimum air pressure of 5bar, and stable lubrication is essential.

l

Operation:

Ø Feed rate:

We recommend that the initial feed rate is f = 3000mm / min. the feed rate must remain unchanged when changing the machining direction, otherwise the chamfer will be inconsistent. The contour program eliminates additional fillets as much as possible.

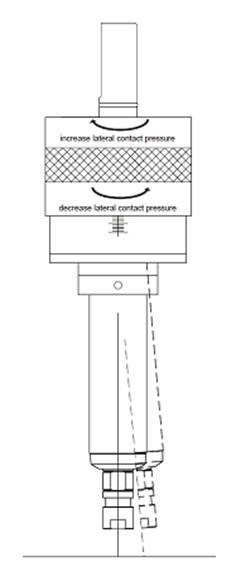

Ø Lateral pressure:

If the rotary file does not work smoothly (for example, the rotary file jumps or there is no real cutting), It indicates that the lateral contact pressure is too small and needs to be increased.

The lateral pressure will also directly affect the chamfer size: generally, the greater the lateral pressure, the greater the chamfer.

Rotate the Yellow adjusting ring clockwise to increase the lateral pressure, and counterclockwise to reduce the lateral pressure.

l method of application

The floating deburring handle of FDT robot has a floating amount of nearly 12mm. The tool follows the program control, and the front-end rotary file must maintain a preload of 1-3mm (lateral pressing amount) during processing

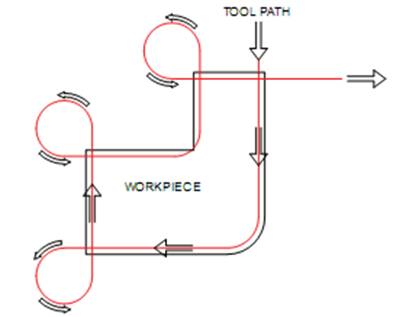

l Machining direction:

The manual floating deburring chamfering tool handle of FDT X36 machine needs forward milling in the processing process (as shown in the figure)

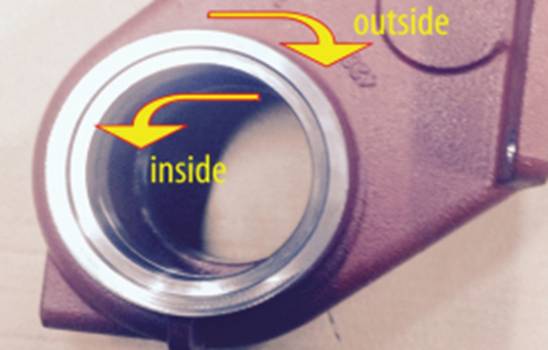

l Chamfer contact point:

Usually we use conical rotary files. According to the requirements of the chamfered profile, the top and tail ends of the rotary file can be used.

If the workpiece shape and holding system allow, we recommend using the tail end of the rotary file as far as possible. This can speed up the processing efficiency and get better processing results.

l Lateral offset (press in):

Ensure that the rotary file has a pre pressing amount during processing, and the rotary file always has a pre offset of 1-3mm relative to the workpiece contour.

l Machining path:

For the floating deburring chamfering cutter, the machining of the inner corner (the junction of both sides) is slightly more complex. Generally, the cutting head cannot contact the two surfaces perpendicular to the inner corner at the same time, because the machining imbalance is easy to cause the vibration of the tool. We suggest adding a tool path where the cutting head does not contact both vertical sides at the same time. The taper cutting head can be closer to such a vertical angle. When it is close to such an internal angle, the tool shall be properly lifted up to make the top of the taper cutting head contact the workpiece (Note: when cutting the top of the head, the machining speed shall be reduced.) When machining to the vertical internal angle of the workpiece, it is necessary to complete the machining of the internal angle through the arc program.

We are the general agent of AKS floating deburring chamfering tool handle in China to provide you with floating deburring solutions and services!

In order to better serve you, please provide the photos (indicating the chamfering area) and drawings of the workpiece for floating chamfering and deburring. We will make the appropriate tool selection for you according to our long-term processing experience!

简体中文

简体中文