EMUGE self locking thread tap LK-M

Causes of thread looseness:

In order to facilitate assembly, there must be a gap between the bolt and the thread. The locking of the thread is guaranteed by the friction between the teeth. Under slight vibration and load, the threaded connection will not loosen. However, under the vibration of heavy load, the internal and external threads will produce lateral displacement due to the gap, so that the friction will disappear. At this time, the threads will be loosened by vibration, even if they are tightened very tightly.

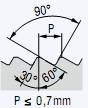

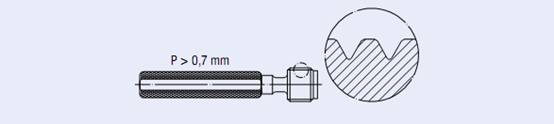

Principle of self-locking thread (locking thread):

When using self-locking thread, the screw is an ordinary screw. The difference is the internal thread. The internal thread profile of self-locking thread is different from that of different threads. Its root has an inclined angle of 30 ° and its middle diameter is increased compared with that of ordinary thread. When the screw is screwed into the self-locking thread, the top of the external thread will contact the 30 ° bevel at the root of the internal thread to produce a clamping force. This contact is actually carried out along the helix on the full length of the thread, so it has a good centering effect, maintains the good concentricity of the bolt and the threaded hole, and prevents relative lateral movement between the threads. Therefore, it will not be released under vibration and transverse load.

Easy disassembly of self-locking thread (locking thread):

Self locking thread (locking thread) does not rely on interference fit for locking. Its loading and unloading is as convenient as ordinary thread and does not require the use of specific tools.

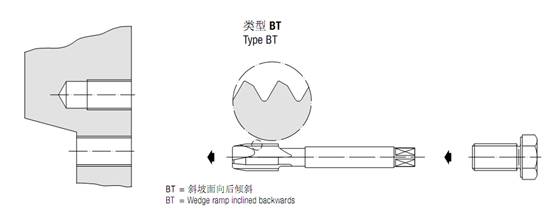

Directionality of self-locking thread (locking thread):

When using self-locking thread tap to process through-hole thread, because the 30 ° inclined edge is directional and cannot be reversed, its tapping direction must be consistent with the bolt threading direction. If reverse hoisting is required in the process, self-locking thread tap with reverse 30 ° inclined angle shall be used

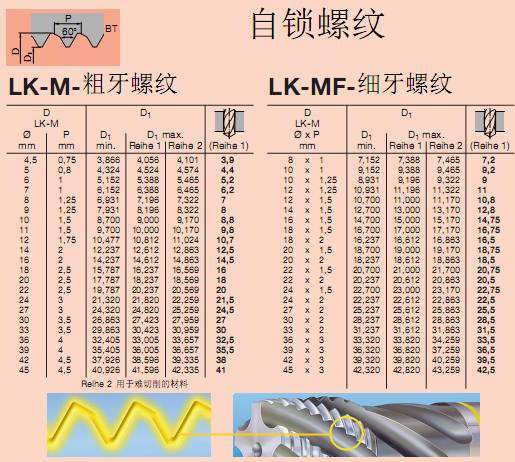

The pre drilled diameter of self-locking thread is larger than the inner diameter of ordinary threaded hole. See the following table for details:

The advantages of using self-locking threads in addition to locking include:

1. Because the pre drilling diameter is increased and the manufacturing tolerance of the pre drilling diameter is enlarged, it is conducive to processing and reduces the metal removal of the tap.

2. The tooth angle of the self-locking thread tap is 90 °, and compared with the 60 ° tooth angle of the ordinary tap, the self-locking thread tap will have higher strength, not easy to wear and longer service life.

3. The minimum pitch diameter of self-locking thread is strictly controlled, and the maximum value is not strictly limited, so the number of regrinding can be more

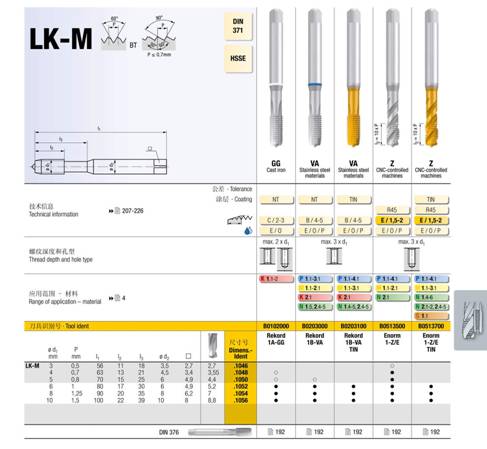

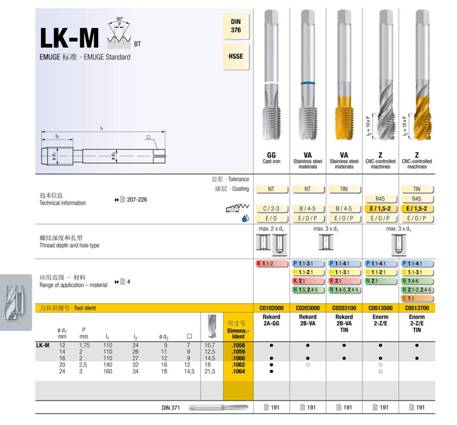

EMUGE self locking thread (locking thread) tap standard selection table:

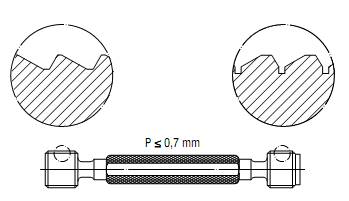

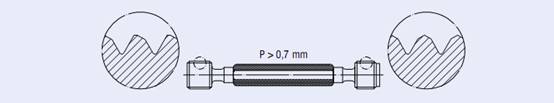

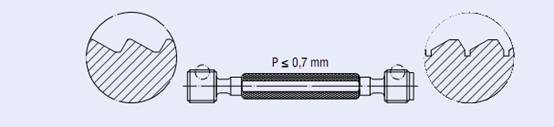

Self locking thread (locking thread) gauge:

We recommend using our two-piece gauge, which is similar to the general gauge (combination of go gauge and no go gauge). It is completely sufficient for the thread processed by using EMUGE self-locking thread tap.

The self-locking thread gauge has the same principle, but the difference is that the through gauge of the plug gauge must pay attention to the correct screw in direction, and the stop rule can be used for screw in in any direction.

If the self-locking thread is machined by using a thread milling cutter, we recommend using the EMUGE HPRG gauge to check the lowest root of the slope and help identify any deviation in the angle of the slope.

Emuge-franken is a group company with a history of more than 90 years providing technology in the fields of thread machining, milling, workpiece clamping and precision measuring tools.

The company's headquarters and production base are located in Rauf city and luxdorf town near Nuremberg, Germany. More than 1000 employees are committed to providing customers with high-performance products and technical services.

简体中文

简体中文