What problems does floating reamer handle mainly solve?

What problems does floating reamer handle mainly solve?

Customers often ask us that after using floating reamer shank:

How about the finish of the hole?

Will the straightness of the hole be good?

The floating reamer handle is used to correct the non concentricity between the reamer and the hole after changing the reamer due to the inaccurate repeated positioning accuracy of the machine tool.

The poor finish of reaming caused by the repeated accuracy of machine tool can be corrected by floating reamer handle.

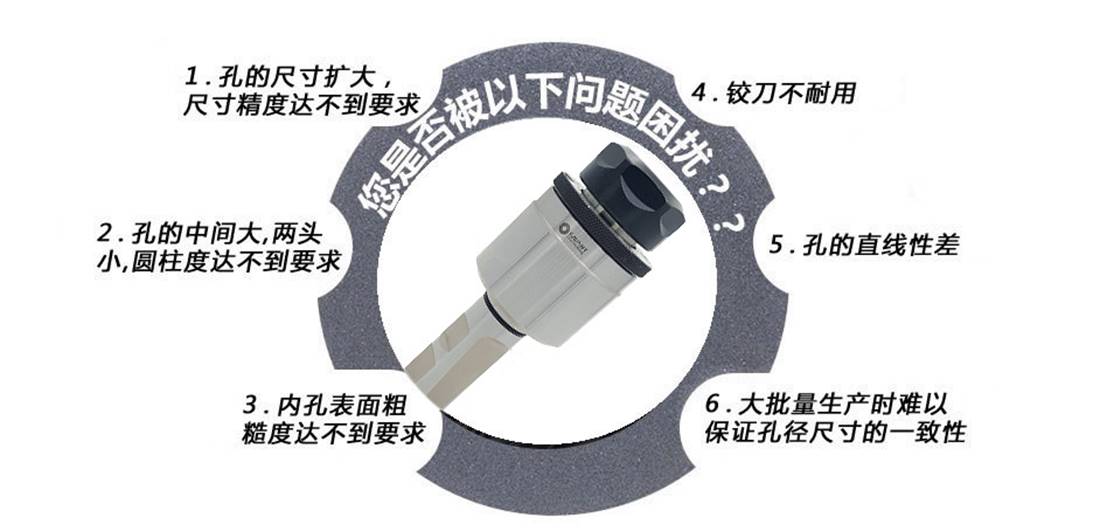

Usually, because the repeated positioning accuracy of the machine tool is not accurate, the reamer will deviate, resulting in inaccurate reaming dimensional accuracy, accelerated reamer wear, large middle and small ends of the reamed hole, linear decline, reduced hole surface roughness, and reduced dimensional consistency during batch processing.

The floating reamer handle can be improved at the following points: Improve dimensional accuracy, reamer durability, cylindricity, straightness, roughness and hole size consistency( The above is based on the problems caused by the repeated positioning accuracy of the machine tool)

简体中文

简体中文