How to use diamond rolling cutter?

How to use diamond rolling cutter?

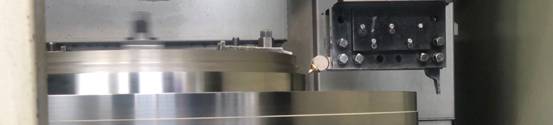

Diamond rolling cutter uses the single crystal diamond in front of the cutter to overcome the yield point of the material in the process of sliding on the workpiece surface under the action of spring force, so as to produce plastic deformation on the material surface and force the highest point of the tool trace to flow into the lowest point, so as to obtain a smooth and flat mirror.

Many people will worry that if they buy a diamond rolling cutter, they know how to use it. In fact, the use of diamond rolling cutter is similar to turning tool, which is very simple.

The interference of diamond rolling cutter is the recommended cutting depth a of turning tool, which is 0.03-0.05mm, the recommended machining speed is 100-200mm / min, and the recommended feed is 0.005-0.02mm/r

Diamond rolling cutter can process a wide range, including workpiece size range and material range. The cylindrical diamond rolling cutter can basically cover all diameter ranges, and the minimum diameter of the inner hole diamond rolling cutter is 15mm.

In the past, the needle type inner hole rolling cutter can only process the workpiece with hardness below hrc40, while the diamond rolling cutter can process the workpiece with HRC60.

What are the key points to pay attention to when using diamond rolling cutter?

It is recommended that the finish of pre-processing should not be lower than ra3.2, otherwise the processing effect will not be ideal. If your pre machined finish is worse than ra3.2, we do not recommend the use of diamond rolling cutter.

简体中文

简体中文