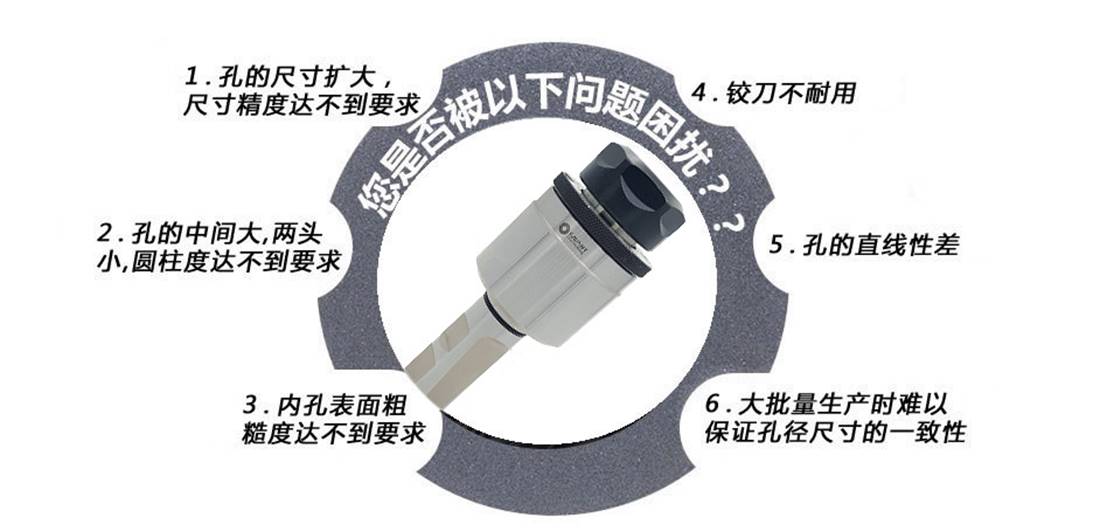

Floating reamer shank

The internal structure of the "floating reamer handle" can realize continuous axial deflection and radial translation, so that the center of the clamped reamer can always float 360 ° radially in its vertical plane around the center of the machine tool spindle. The deviation between the reamer center and the machined hole center is made up, the relocation error of the reamer is eliminated, and the reamer center is consistent with the machined hole center in the whole machining process.

Applicable machine tools: lathe, milling machine, machining center, drilling machine and special machine

ER25 adjustable floating reamer shank (with central internal cooling)

1. When the centering sleeve is fully tightened, it shall be locked radially without floating clearance. The radial floating distance increases by 0.05mm and the maximum radial clearance is 1mm when the scale on the disc surface of the centering sleeve rotates one grid.

2. The structural design inside the shank can realize the free floating of the reamer axis within the maximum axial range of 1 °, and automatically compensate the angular deviation between the center of the pre machined hole and the machine tool spindle.

Model | D | D1 h6 | D2 | L | L1 | L2 | Fmax |

SV-FTER25-D25 | 52 | 25 | 40 | 133.5 | 58 | 15 | 1 |

SV-FTER25-D20 | 52 | 20 | 40 | 113.5 | 40 | 15 | 1 |

Automatic centering floating reamer shank

Features of automatic return to center: it can return to center automatically on lathes (including vertical and horizontal lathes) and machining centers. The floating direction is parallel to the axis of the rotating shaft to automatically compensate the shaft deviation between the collet and the hole to be machined.

The automatic centering can adjust the floating resistance in the centering through the adjustment mechanism according to the tool weight, so as to prevent vibration and prolong the tool life.

Er11m automatic centering floating reamer shank

Model | D | D1 h6 | D2 | L | L1 | L2 | F(two-way) |

SV-FTER11M-D16(HZ) | 25 | 16 | 19 | 75 | 42 | 15 | 1 |

SV-FTER11M-D19.05(HZ) | 25 | 19.05 | 19 | 75 | 42 | 15 | 1 |

SV-FTER11M-D20(HZ) | 25 | 20 | 19 | 75 | 42 | 15 | 1 |

SV-FTER11M-D22(HZ) | 25 | 22 | 19 | 75 | 42 | 15 | 1 |

SV-FTER11M-D25(HZ) | 25 | 25 | 19 | 75 | 42 | 15 | 1 |

SV-FTER11M-D25.4(HZ) | 25 | 25.4 | 19 | 75 | 42 | 15 | 1 |

ER25 automatic centering floating reamer shank

Model | D | D1 h6 | D2 | L | L1 | L2 | F(two-way) |

SV-FTER25-D16(HZ) | 52 | 16 | 40 | 127 | 58 | 30 | 2 |

SV-FTER25-D19.05(HZ) | 52 | 19.05 | 40 | 127 | 58 | 30 | 2 |

SV-FTER25-D20(HZ) | 52 | 20 | 40 | 127 | 58 | 30 | 2 |

SV-FTER25-D22(HZ) | 52 | 22 | 40 | 127 | 58 | 30 | 2 |

SV-FTER25-D25(HZ) | 52 | 25 | 40 | 127 | 58 | 30 | 2 |

SV-FTER25-D25.4(HZ) | 52 | 25.4 | 40 | 127 | 58 | 30 | 2 |

Actual shooting of products:

We will show you the details of deburring tools, floating reamer shanks, rolling heads and diamond rolling cutters provided by our company, as well as the products represented by our company: TOOLFLO, EMUGE, HEULE and other brands

Deburring tools include: integral deburring chamfering cutter, disposable deburring chamfering cutter, HEULE deburring chamfering cutter, HSD deburring chamfering cutter and AKS deburring chamfering cutter handle. Through the above tools, we can provide customers with perfect machining deburring solutions.

Floating reamer handle: we usually call it floating reamer handle or reamer floating reamer handle, which is used to make up for the repositioning error of the machine tool, improve the reamer processing effect and increase the service life of the reamer.

Rolling cutter: also known as rolling head, it has inner hole rolling head, outer circle rolling head, end surface rolling head and other non-standard rolling heads.

Diamond rolling cutter: it is an independent one separated from the rolling head system. There are diamond rolling cutters that can be used to process outer circles and inner holes. At the same time, diamond rolling cutters can also be used for end surface. Through the program control of machine tools, rolling of various shapes can be realized like turning tools. A diamond rolling cutter can cover most of the processing surfaces. Low comprehensive use cost.

简体中文

简体中文