SAVANTEC sevante eccentric reverse scraper

Eccentric reverse counterbore cutter

Eccentric reverse chamfering cutter

SAVANTEC eccentric reverse scraper requires the machine tool to have directional stop function, otherwise it cannot be used.

SAVANTEC eccentric reverse scraper requires the machine tool to have directional stop function, otherwise it cannot be used.

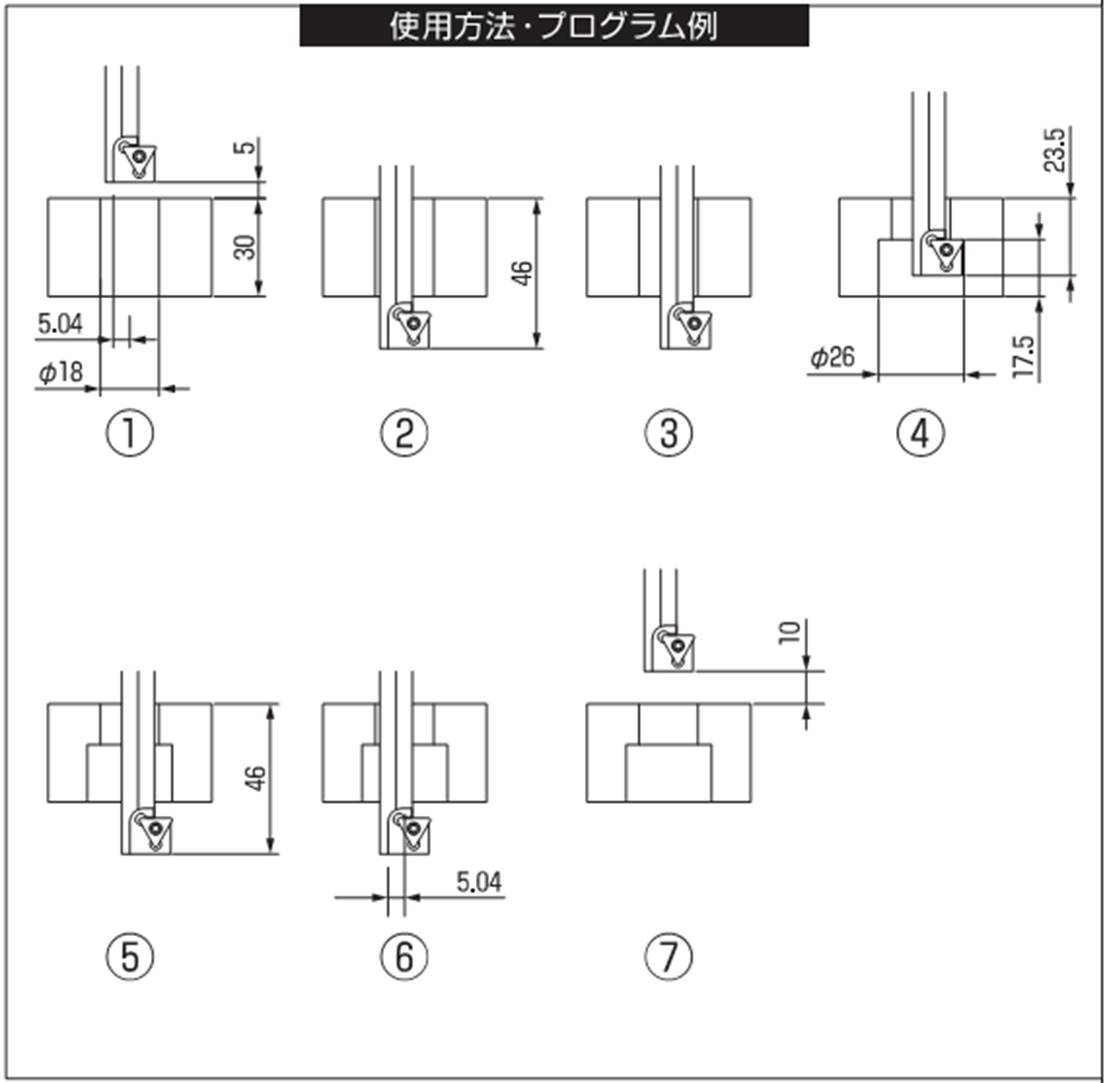

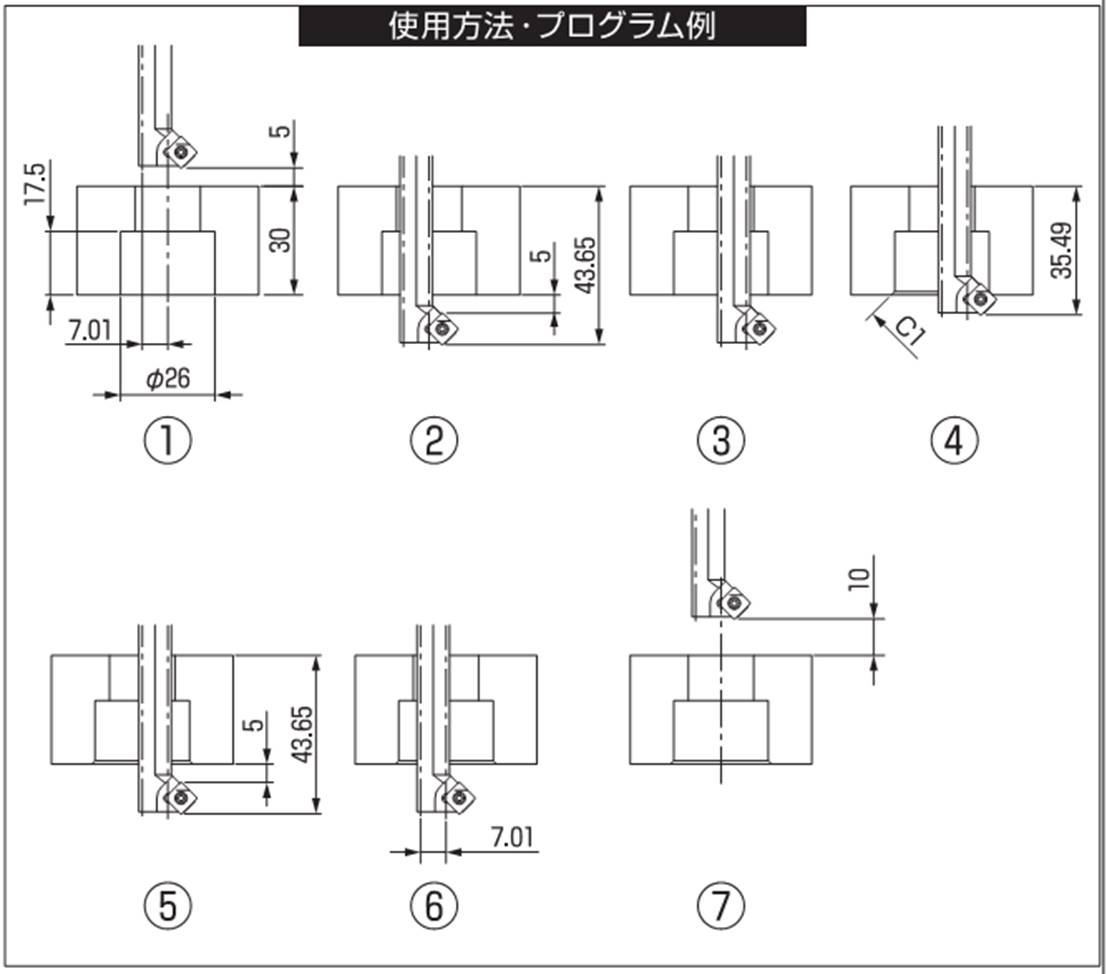

Processing steps of reverse scraper: 1. Spindle positioning |  |  |

SAVANTEC eccentric reverse scraper features:

l Reduce secondary processing and increase fine-tuning structure to process more accurate counterbore.

l No forward and reverse rotation is needed to reduce the probability of damage.

l Special design, good body rigidity.

l Reduce the cumbersome process of manually installing the cutter head, and import it for processing and forming at one time.

l We accept all specification customization. For the case that the counterbore is much larger than the bottom hole, we will choose imported alloy steel or plug cemented carbide or use integral tungsten base alloy as the body.

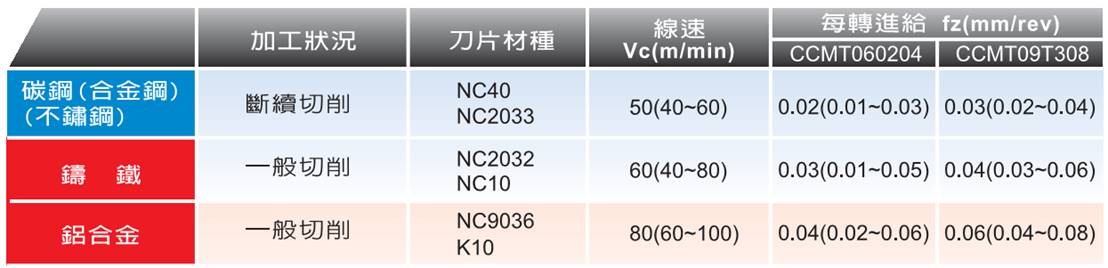

Recommended processing parameters:

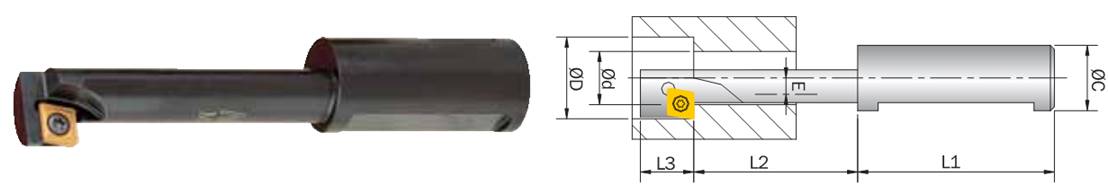

Product picture

Click to watch the video: in order not to affect others, you can turn off the music before watching the video

SAVANTEC sleeve reverse scraper

Processing steps of SAVANTEC sleeve reverse scraper:

First extend the z-axis of the cutter bar; Then insert the cutter head easily; Rotate the cutter head to clamp the main cutter rod; Forward turning upward processing; Return and remove the cutter head; The tool bar exits and the machining is completed.

SAVANTEC sleeve reverse scraper features:

u Suitable for a variety of machine tools: Machining Center, boring and milling machine, rocker drill, bench drill, etc

u The cutterhead is easy to install and insert without screw fixation, saving time

u The blade can be designed to be disposable.

The following is a blade mounted reverse scraper with screw structure: the advantages are tight installation, sufficient rigidity, replaceable blade and low cost. The disadvantage is that it takes a lot of time to change the tool.

We will show you the details of deburring tools, floating reamer shanks, rolling heads and diamond rolling cutters provided by our company, as well as the products represented by our company: TOOLFLO, EMUGE, HEULE and other brands

Deburring tools include: integral deburring chamfering cutter, disposable deburring chamfering cutter, HEULE deburring chamfering cutter, HSD deburring chamfering cutter and AKS deburring chamfering cutter handle. Through the above tools, we can provide customers with perfect machining deburring solutions.

Floating reamer handle: we usually call it floating reamer handle or reamer floating reamer handle, which is used to make up for the repositioning error of the machine tool, improve the reamer processing effect and increase the service life of the reamer.

Rolling cutter: also known as rolling head, it has inner hole rolling head, outer circle rolling head, end surface rolling head and other non-standard rolling heads.

Diamond rolling cutter: it is an independent one separated from the rolling head system. There are diamond rolling cutters that can be used to process outer circles and inner holes. At the same time, diamond rolling cutters can also be used for end surface. Through the program control of machine tools, rolling of various shapes can be realized like turning tools. A diamond rolling cutter can cover most of the processing surfaces. Low comprehensive use cost.

简体中文

简体中文