How to reverse deburr threaded holes

How to reverse deburr threaded holes

When machining threaded holes, customers will find that the diameter (especially the large diameter) edge of the threaded hole is full of burrs, which is easy to cause the bolt to jam and inconvenient for installation in the process of bolt locking. And it is particularly easy to fall off during the use of later workpieces, resulting in irreparable losses.

How to use the deburring tool on the front and back of the orifice to remove the burrs on the front and back of the threaded hole?

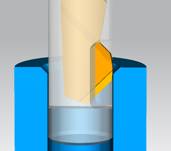

Firstly, because the deburring and chamfering tool on the front and back of the orifice is an elastic working principle, the blade will squeeze the thread tip when passing through the thread in the hole, thus affecting the teeth to a certain extent. Unless the customer's internal thread requirements are not high, it is not recommended that the customer use positive and negative deburring and chamfering tools after machining the thread.

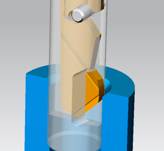

Usually, we recommend customers to use our deburring and chamfering tools on the front and back of the orifice to process the threaded bottom hole at one time and chamfering on both sides before machining the thread. We will select the tool with the largest chamfer for customers to make the chamfer size larger than the thread pitch after customers' machining, so that the chamfer still exists after customers' tapping to avoid burrs.

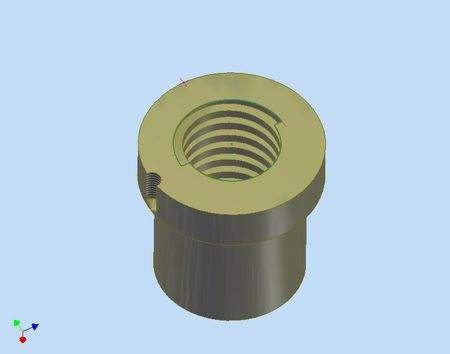

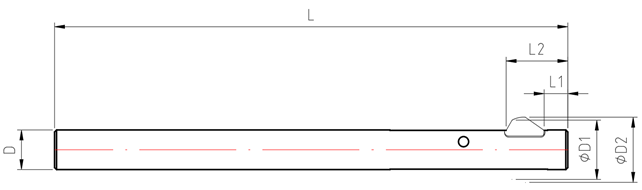

Our SV-BW disposable deburring and chamfering tool for front and back orifices takes into account the customer's requirements for large chamfering size at the beginning of blade size design. Therefore, it can be used to remove the two-way burr of the threaded hole.

简体中文

简体中文