Classification of oil path tool handle (external cooling to internal cooling tool handle)

Classification of oil path tool handle (external cooling to internal cooling tool handle)

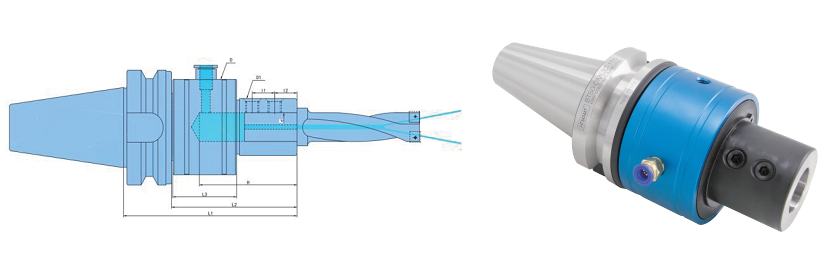

The oil path tool handle (external cooling to internal cooling tool handle) is suitable for the use of internal cooling tools, and can quickly realize the function of external cooling to internal cooling of machine tools.

High pressure internal cooling can effectively remove iron filings, improve machining efficiency, reduce cutting edge temperature and prolong bit service life.

There are many kinds of oil knife handles on the market. How should we choose?

According to the applicable machine tools, we divide the oil path tool handle into categories, so that we can more easily choose our own oil path tool handle (external cooling to internal cooling tool handle).

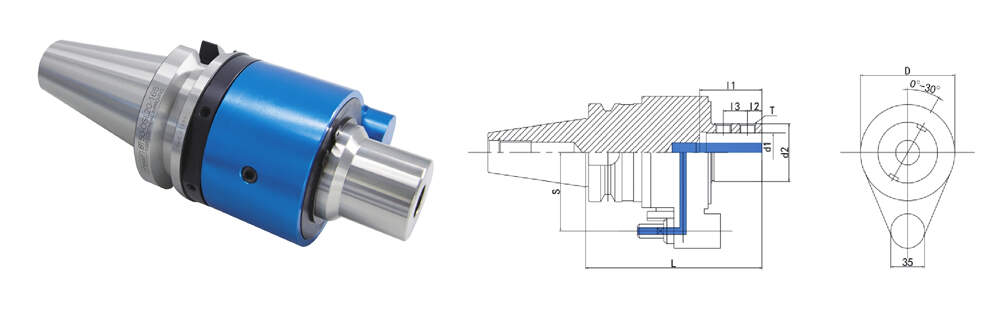

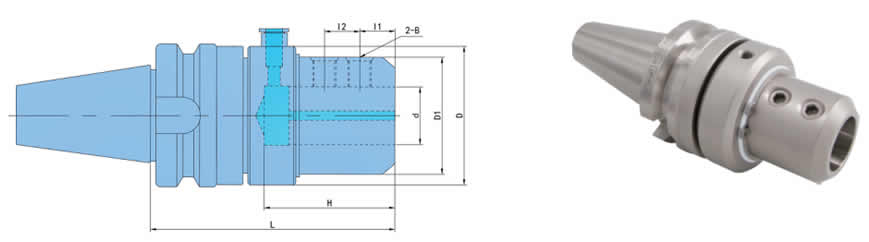

A bearing type (high speed)

1. The utility model relates to an automatic tool changing oil path tool handle suitable for the machining center. The tool handle is installed on the machining center and can realize automatic tool changing like other ordinary tool handles without manual installation every time.

A positioning block is used with the automatic tool changing oil path tool handle. The positioning block is installed on the end surface of the machine tool spindle and butted with the screw hole on the end surface to limit the rotation of the shell of the oil path tool handle. The form is similar to the angle head. Please refer to the "installation and use instructions" for the installation and use of the tool handle of the automatic tool changing oil circuit

The oil path tool handle is a high-speed tool handle, and the limited speed is 3000rpm.

See the installation and operation instructions of the tool handle of the high-speed automatic tool change oil circuit for details:

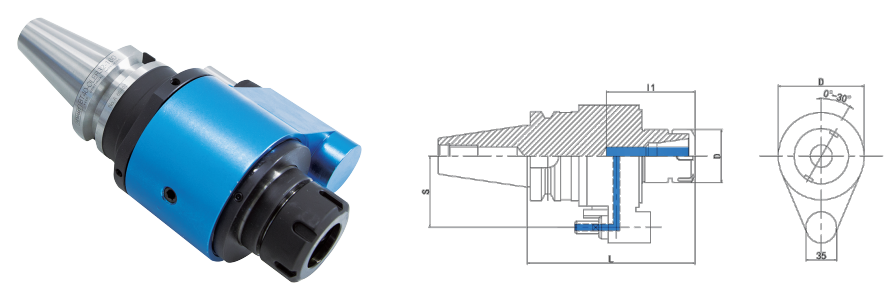

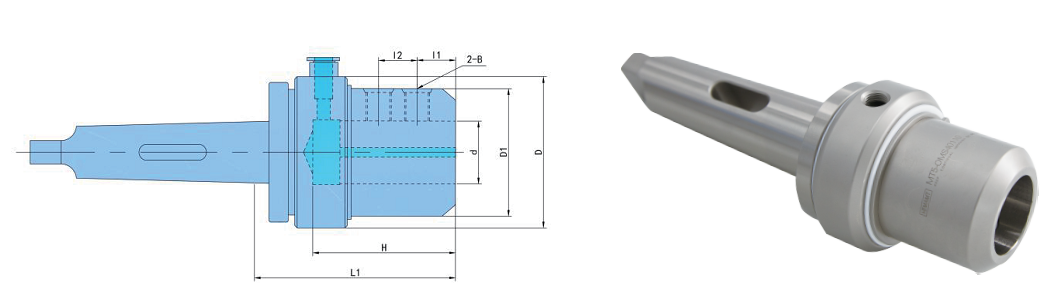

2. It is suitable for boring and milling machines, rocker drills, etc. the tool handle is locked with the screws on the side of the tool handle through one section of the limit rod, and the other end can be fixed through the rod provided by the customer, so as to limit the rotation of the tool handle shell.

The oil path tool handle is suitable for the working condition without automatic tool change, with simple use and convenient maintenance.

The oil passage tool handle is of bearing structure (high-speed oil passage tool handle), and the speed limit of high-speed oil passage tool handle is 3000rpm

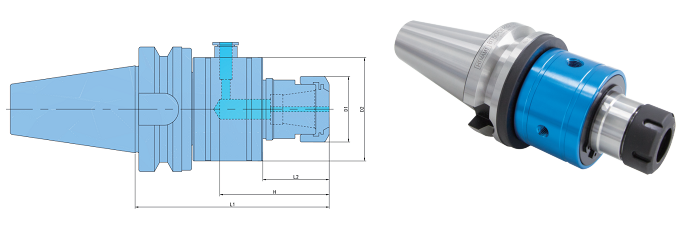

B sealing ring type (low-speed oil passage tool handle)

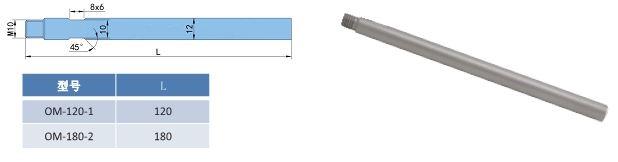

3. It is suitable for low-speed boring machines, rocker drills, lathes and other machine tools. The tool handle is also locked with the screws on the side of the tool handle through one section of the limit rod, and the other end is fixed through the rod provided by the customer, so as to limit the rotation of the tool handle shell. The oil path tool handle is suitable for the working condition without automatic tool change, with simple use and convenient maintenance.

However, compared with the high-speed tool handle mentioned above, its speed is limited to 1000 rpm, otherwise it is easy to damage the sealing ring.

The low-speed oil path tool handle will slowly withdraw from the historical stage except that the Mo handle will continue to be used on the lathe.

简体中文

简体中文