Deburring case of chamfering front and back sides of threaded bottom hole

Deburring and chamfering cutter for front and back of inner hole

Deburring case of chamfering front and back sides of threaded bottom hole

Product Name: spiral case (base)

Material: ductile iron

Thread size: M10

Size of threaded bottom hole: D8.5

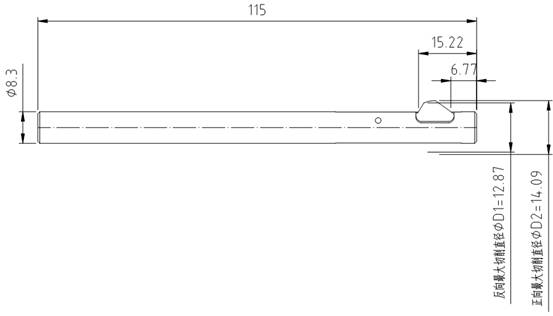

Tool selection: SV-BW-8.5

Tool setting: chamfer the thread bottom hole. The size of one side of the chamfer must be greater than the pitch so that there is no secondary burr after tapping. For example, the chamfer size of M10 threaded bottom hole must be greater than 1.5mm.

By adjusting the elastic force of the tool tail, adjust the spring and rotate it inward for 6 turns to make the blade elastic enough.

Tool drawing:

Machining parameters during blade cutting period: rotating speed n = 1200, feed f = 150( Non cutting edge cutting period (F = 3000 - fast forward and fast backward)

Picture of processing effect after tapping: no burr or secondary flanging after tapping.

If you have more requirements for chamfering and deburring threaded holes,请点击Please click disposable deburring chamfering cutter to view the details! View details!

Or contact us directly!

简体中文

简体中文