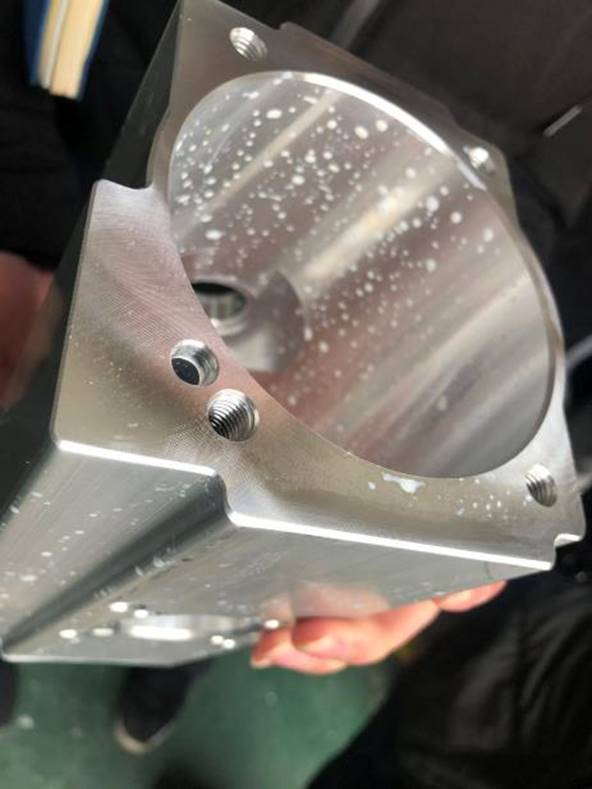

Floating chamfer deburring of motor casing contour

Floating chamfer deburring of motor casing contour

There will be milling burrs on the contour of the motor casing after surface milling, which is time-consuming and laborious if manual machining is used.

The customer used the rigid chamfering cutter to process the contour burr before. Because of the casing casting error and clamping error, there are uneven chamfering - some places can be inverted to the corner, some places can not be inverted. If the contour program is retracted, the chamfer size will be different, and the size difference can reach more than 1mm.

After using the floating deburring chamfering handle, use the 45 ° rotary file to control the cutting amount and adjust the feed speed through the Z axis to achieve a relatively consistent chamfering size. The customer is satisfied with the use result.

The rotary file is clamped by the floating deburring tool handle to remove the burr of the uneven contour (edge) and automatically compensate between the actual contour of the workpiece and the program.

For product details, please click: Floating deburring handle

简体中文

简体中文